Pipe Bursting

What is it?

It is a method of repairing water supply networks without the need for trenching.

This system does not require the use of chemicals or other contaminants, which, combined with the fact that the PEAD pipe has an expected life span of over 50 years, makes this technology environmentally safe and sustainable.

How does it work?

This construction method allows for the renewal of water networks while maintaining normal supply to customers by installing a temporary bypass structure.

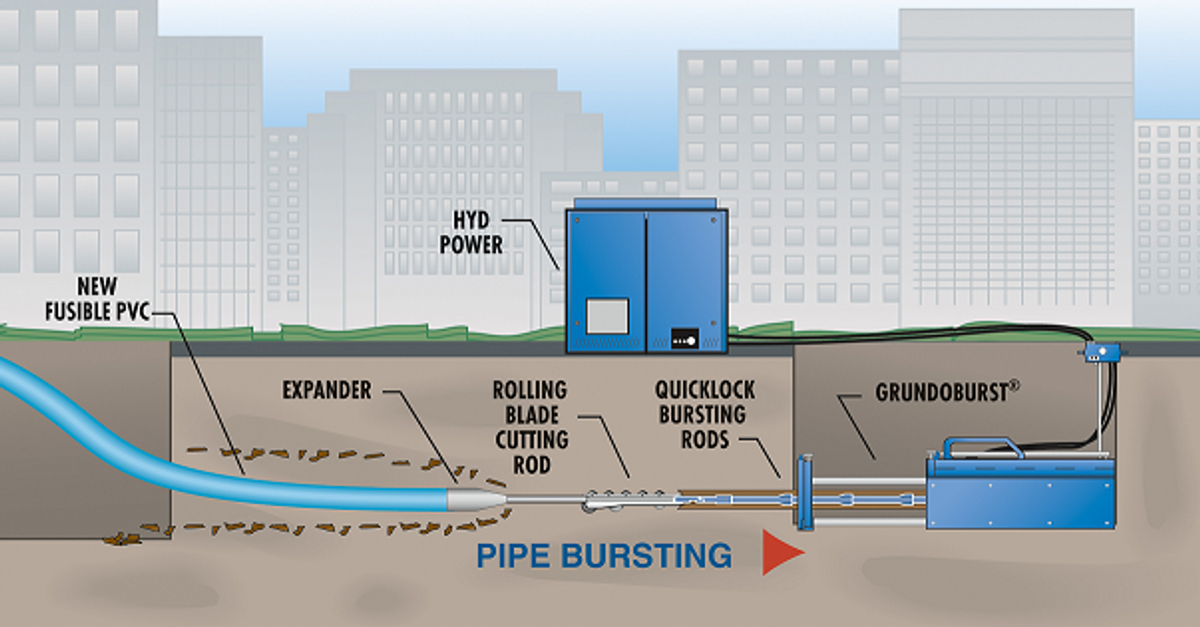

The existing pipe is ruptured by pulling an expanding head through the old pipe. This head, also known as a cone, is sized to fit the existing pipe and, with the help of blades, fractures the installed pipe as it is pulled.

The back of the head is connected to the new pipe, which, fixed to this element, is dragged into the existing pipe at the pace of the expander's advance.

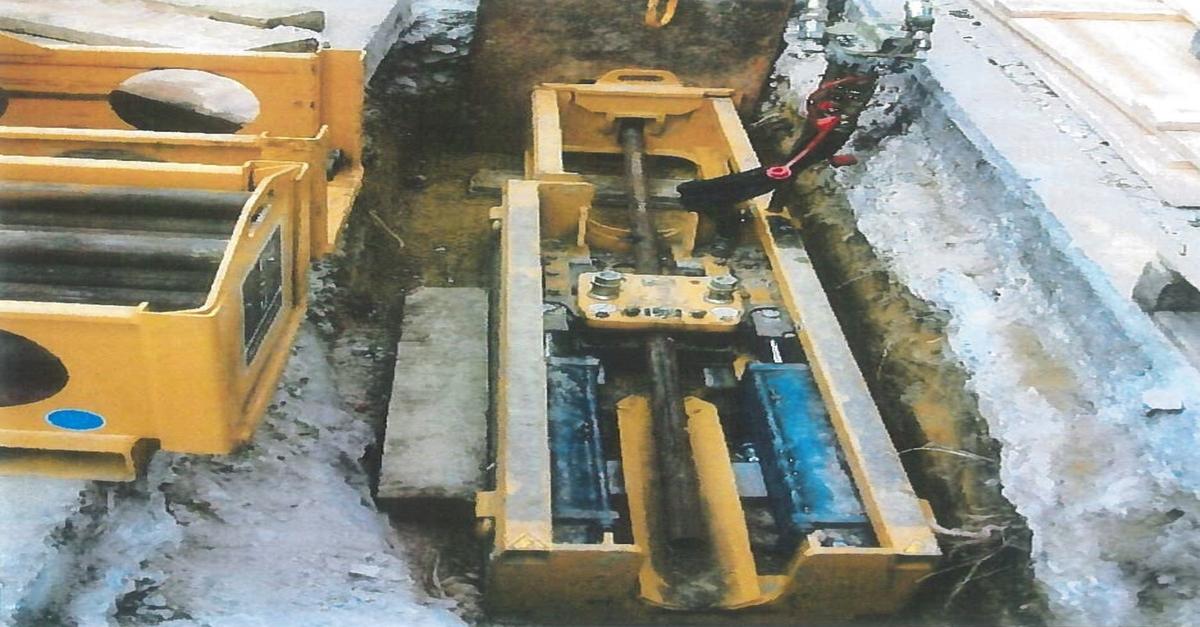

The equipment's energy comes from the hydraulic system, which is connected to traction rods that are in turn attached to the expander's head. This assembly is placed inside an attack pit, built at the level of the existing pipe. At this stage, the metal rods are introduced, which, upon reaching the end of the section to be repaired, begin their work of rupturing, expanding the installed conduit, and inserting the new pipe.

Quais as suas vantagens?

- Yields of up to 100m/day (in "normal" soil conditions), but can be higher in less compact soils (soft ground or sand areas);

- Can be used with a wide variety of internal pipe diameters;

- Virtually all common pipe materials used in water supply networks can be replaced using this system;

- Significant reduction in labor and execution time requirements;

- Strong decrease in earthmoving work (only needed for the construction of attack pits, which in straight lines will be at least 100m apart for equipment operation);

- In areas with tight curves or abrupt changes in direction, pipe renewal will have to be done through the traditional trench excavation system;

- Allows for the replacement with a larger section of pipe than installed – the percentage of this increase is defined according to the pipe type and soil type, but can reach up to 50% of the installed pipe;

- This equipment is guided by the existing infrastructure, which facilitates its operation;

- Reduces the risk of causing damage to adjacent existing infrastructures;

- Can be used regardless of the existing pipe's condition;

- Decreases social impact by reducing surface disturbances in areas to be intervened, especially in urbanized areas (people and vehicle circulation);